Table of Contents

- 1. Why Cashmere Quality Is Often Misunderstood

- 2. Fiber Length: One of the Most Important Indicators

- 3. Fiber Fineness: Softness with a Trade-Off

- 4. Pilling: The Most Honest Quality Test

- 5. Yarn Structure: Single-Ply vs Multi-Ply Cashmere

- 6. Knitting Density and Gauge

- 7. Weight and Substance: Why “Thicker” Often Means Better

- 8. Finishing Processes That Separate Good from Great

- 9. Shape Retention: A Long-Term Quality Indicator

- 10. Color and Dye Quality

- 11. Smell and Touch: Subtle Sensory Clues

- 12. Labeling and Transparency

- 13. Price: Understanding the Real Cost of Quality Cashmere

- 14. Washing Performance: The Ultimate Test

- 15. Manufacturer Expertise Matters More Than Marketing

- Final Thoughts

Cashmere is often described as one of the most luxurious fibers in the world. However, as global demand has increased, the market has become increasingly complex. Today, products labeled as “cashmere” can vary dramatically in softness, durability, and long-term value.

Cashmere is produced from the fine undercoat of cashmere goats and is considered one of the rarest animal fibers in the world. According to the Food and Agriculture Organization of the United Nations (FAO) , each goat yields only a limited amount of usable cashmere fiber per year, which directly impacts both availability and cost across the global market.

This is why searches such as how to tell if cashmere is high quality, good quality cashmere, and real cashmere vs low quality cashmere continue to grow year after year.

The reality is simple: not all cashmere is created equal.

This guide explains how to evaluate cashmere quality from a practical and manufacturing-informed perspective, helping buyers, brands, and retailers understand what truly defines high-quality cashmere—beyond marketing claims and first-touch softness.

1. Why Cashmere Quality Is Often Misunderstood

For many consumers, cashmere quality is judged by one factor: softness. While softness is important, it is only one part of a much larger equation.

Low-quality cashmere can feel extremely soft at first touch, especially when:

● Short fibers are heavily processed

● Garments are over-finished to enhance surface feel

However, these products often pill quickly, lose shape, and deteriorate after limited wear.

High-quality cashmere, by contrast, balances:

● Softness

● Fiber strength

● Structural stability

● Long-term performance

Understanding this balance is the key to identifying true quality.

2. Fiber Length: One of the Most Important Indicators

The length of the cashmere fiber is one of the strongest predictors of quality.

Why Fiber Length Matters

Longer fibers:

● Spin into stronger yarns

● Reduce fiber ends on the surface

● Significantly decrease pilling

● Improve garment lifespan

Short fibers, while softer initially, break and migrate to the surface more easily, causing visible pilling.

High-quality cashmere garments almost always use longer staple fibers, even if they feel slightly less “buttery” at first touch.

3. Fiber Fineness: Softness with a Trade-Off

Fiber fineness determines how soft cashmere feels against the skin, but softness always comes with a trade-off. As explained by The Woolmark Company, extremely fine fibers enhance hand feel, while slightly thicker fibers often perform better in terms of strength and abrasion resistance when used for everyday garments.

● Finer fibers = softer hand feel

● Slightly thicker fibers = better durability

Extremely fine fibers can create a luxurious sensation but may compromise abrasion resistance if not properly balanced.

Experienced manufacturers carefully select fiber fineness based on the intended use of the garment—everyday wear requires different specifications than luxury layering pieces.

4. Pilling: The Most Honest Quality Test

Pilling is often misunderstood as a defect. In reality, all cashmere will pill to some degree. Pilling is a natural characteristic of cashmere. According to Consumer Reports, pilling occurs when short or weak fibers migrate to the surface during friction, making it one of the most honest indicators of underlying fiber quality.

The key difference is how quickly and how severely pilling occurs.

High-quality cashmere:

● Pills minimally

● Pills gradually

● Stabilizes after initial wear

Low-quality cashmere:

● Pills heavily after a few wears

● Continues to shed fibers

● Looks worn very quickly

If a cashmere sweater pills excessively within the first few uses, it is usually a sign of short fiber content or weak yarn structure.

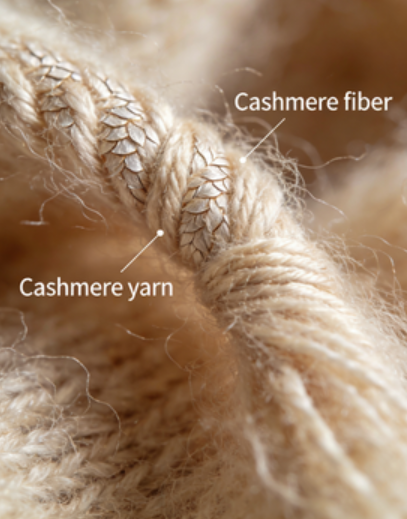

5. Yarn Structure: Single-Ply vs Multi-Ply Cashmere

Yarn construction plays a critical role in garment performance.

Single-Ply Cashmere

● Softer initial feel

● Lower production cost

● Higher risk of pilling and deformation

Two-Ply (or Multi-Ply) Cashmere

● Stronger yarn structure

● Better shape retention

● Longer garment lifespan

High-quality cashmere sweaters are typically made with 2-ply yarn, especially for core styles intended for repeated wear.

6. Knitting Density and Gauge

How tightly a sweater is knitted has a major impact on quality. Knitting density and gauge determine how tightly yarns are interlocked within a fabric. According to Wikipedia, gauge refers to the number of stitches per unit of measurement and directly influences fabric strength, elasticity, and long-term dimensional stability.

Loose knitting:

● Feels soft and light

● Stretches easily

● Loses shape over time

Properly balanced knitting:

● Maintains elasticity

● Holds shape after washing

● Improves durability

A high-quality cashmere sweater will feel cohesive and resilient, not flimsy or overly delicate.

7. Weight and Substance: Why “Thicker” Often Means Better

While lightweight cashmere has its place, extremely thin garments often sacrifice longevity.

High-quality cashmere sweaters usually have:

● Adequate weight for their style

● Even distribution of yarn

● A sense of substance when worn

Weight consistency also reflects good manufacturing control.

8. Finishing Processes That Separate Good from Great

Finishing is where many quality differences become visible. Many professional manufacturers align their internal procedures with internationally recognized frameworks provided by the International Organization for Standardization (ISO) to ensure consistency, dimensional stability, and controlled shrinkage across production batches.

High-quality cashmere undergoes:

● Controlled washing to reduce shrinkage

● De-hairing to remove coarse fibers

● Steam shaping to stabilize dimensions

Low-quality products may skip or minimize these steps, resulting in garments that change dramatically after washing.

9. Shape Retention: A Long-Term Quality Indicator

One of the clearest signs of high-quality cashmere is how well it holds its shape.

After wearing and washing, a quality sweater should:

● Return to its original dimensions

● Maintain neckline and cuff elasticity

● Avoid sagging at elbows or hem

Poor shape retention usually points to weak yarn structure or improper finishing.

10. Color and Dye Quality

Color can also reveal quality.

Light and neutral shades (beige, ivory, camel):

● Expose fiber impurities

● Require cleaner raw material

● Demand precise dye control

Uneven color or dull appearance often indicates lower fiber quality or rushed dyeing processes.

11. Smell and Touch: Subtle Sensory Clues

While not definitive, certain sensory cues can help.

High-quality cashmere:

● Has little to no chemical odor

● Feels warm and breathable

● Does not feel overly slick or “siliconized”

An unnaturally smooth, slippery feel may indicate heavy chemical finishing designed to mask poor fiber quality.

12. Labeling and Transparency

Quality brands and manufacturers are usually transparent about:

● Fiber composition

● Country of manufacture

● Care instructions

Vague labeling or lack of information can be a red flag, especially in higher price ranges.

13. Price: Understanding the Real Cost of Quality Cashmere

True high-quality cashmere cannot be extremely cheap.

Factors that influence cost include:

● Raw fiber yield

● Sorting and de-hairing loss

● Yarn spinning standards

● Finishing intensity

While price alone does not guarantee quality, unrealistically low prices often signal compromises.

14. Washing Performance: The Ultimate Test

After proper washing, high-quality cashmere should:

● Retain softness

● Maintain size

● Show minimal surface change

Garments that shrink, harden, or pill heavily after washing rarely meet high-quality standards.

15. Manufacturer Expertise Matters More Than Marketing

Behind every high-quality cashmere product is a manufacturer who understands:

● Fiber selection

● Yarn engineering

● Knitting balance

● Finishing discipline

Quality is the result of technical decisions, not just branding.

Final Thoughts

Learning how to tell if cashmere is high quality requires looking beyond first impressions. True quality reveals itself through fiber length, yarn structure, knitting balance, finishing processes, and long-term performance.

For buyers, brands, and retailers, understanding these fundamentals leads to better sourcing decisions, fewer quality issues, and more sustainable product lines.High-quality cashmere is not just softer—it is stronger, more stable, and made to last.

For high-quality cashmere sweater sourcing, manufacturing expertise makes the difference.