As global demand for premium knitwear continues to rise, search terms such as wholesale cashmere sweater, OEM cashmere sweater, and cashmere sweater supplier show strong and consistent commercial intent. These keywords are typically used not by end consumers, but by brands, retailers, and wholesalers actively looking for reliable manufacturing partners.

However, sourcing cashmere sweaters successfully involves far more than comparing prices or minimum order quantities. From a manufacturer’s perspective, many OEM and wholesale projects fail—or underperform—not because of design issues, but because of incomplete technical understanding during early development.

This article provides a comprehensive, manufacturer-driven explanation of how OEM and wholesale cashmere sweater production actually works, including MOQ logic, cost structure, quality control, and long-term supplier collaboration.

Table of Contents

- 1. Understanding OEM vs Wholesale in Cashmere Sweater Production

- 2. What Determines MOQ in Cashmere Sweater Manufacturing

- 3. MOQ Ranges You Can Expect in Practice

- 4. Cashmere Sweater Cost Structure Explained

- 5. Why “Lowest Price” Often Becomes the Highest Risk

- 6. Yarn Strategy: Stock vs Custom Development

- 7. Sampling and Development: What Buyers Should Expect

- 8. Lead Time Expectations in OEM and Wholesale Programs

- 9. Quality Control in Bulk Cashmere Sweater Production

- 10. Managing Shrinkage, Pilling, and Shape Retention

- 11. Packaging, Labeling, and Export Considerations

- 12. Communication Mistakes That Delay Production

- 13. Why Early Manufacturer Involvement Improves Results

- 14. Long-Term Supplier Relationships vs One-Off Orders

- 15. How to Evaluate a Cashmere Sweater Manufacturer

- Final Thoughts

1. Understanding OEM vs Wholesale in Cashmere Sweater Production

Before discussing cost and MOQ, it is important to clarify the difference between OEM and wholesale sourcing models in cashmere sweater manufacturing.

OEM (Original Equipment Manufacturing)

From a commercial standpoint, OEM models are widely used across manufacturing industries, as defined by Investopedia’s explanation of OEM manufacturing, which emphasizes customization and brand ownership over production assets.

OEM production typically involves:

• Buyer-provided designs or specifications

• Customized yarn, color, and sizing

• Brand-specific labeling and packaging

OEM programs offer higher differentiation but require more technical coordination and development time.

Wholesale Programs

Wholesale production usually focuses on:

• Manufacturer-developed or semi-custom styles

• Stock yarn and standard colors

• Faster lead times and lower MOQs

Wholesale sourcing is often used for market testing or quick replenishment.Understanding which model fits your business strategy directly affects MOQ, cost, and lead time.

2. What Determines MOQ in Cashmere Sweater Manufacturing

MOQ is one of the most frequently misunderstood aspects of cashmere sourcing. From a manufacturer’s standpoint, MOQ is not an arbitrary number—it is driven by multiple technical and logistical factors.

Key Factors That Influence MOQ

Yarn Availability

• Stock yarn: lower MOQ, faster production

• Custom-dyed yarn: higher MOQ due to dye lot requirements

Color Quantity

Each color requires a separate dye lot. Increasing color options increases MOQ proportionally.

Design Complexity

Complex stitches, special trims, or custom gauges increase setup costs, pushing MOQ higher.

Manufacturers with strong yarn sourcing capabilities may offer flexible MOQs, especially for long-term partners.

3. MOQ Ranges You Can Expect in Practice

While MOQs vary, typical ranges for cashmere sweater production include:

• 120–200 pcs per style/color using stock yarn

• 300–500 pcs per style/color for custom-dyed yarn

• Higher MOQs for blended or specialty constructions

Buyers should view MOQ as a function of production efficiency, not simply a negotiation point.

4. Cashmere Sweater Cost Structure Explained

Understanding cost structure helps buyers evaluate quotations more accurately.

Main Cost Components

Raw Material

Cashmere fiber quality, yarn count, and ply structure significantly influence cost.

Knitting and Labor

Higher gauges, complex patterns, and tighter tolerances increase labor time.

Finishing Processes

De-hairing, pre-washing, steam shaping, and anti-pilling treatments add cost but improve long-term performance.

Quality Control

Multi-stage inspections reduce defect rates but require additional labor input.Transparent manufacturers can explain how each component contributes to the final price.

5. Why “Lowest Price” Often Becomes the Highest Risk

From a manufacturer’s experience, aggressive price-driven sourcing often results in:

• Reduced finishing processes

• Lower yarn quality

• Inconsistent bulk performance

These shortcuts may not be visible in samples but frequently surface after market launch, leading to returns and brand damage.

6. Yarn Strategy: Stock vs Custom Development

Stock Yarn Programs

Advantages:

• Lower MOQ

• Shorter lead times

• Stable quality

Limitations:

• Limited color range

• Less differentiation

Custom Yarn Development

Advantages:

• Brand-specific positioning

• Customized softness or weight

Considerations:

• Higher MOQ

• Longer development timeline

Manufacturers often recommend starting with stock yarn for initial programs, then moving to custom development once volumes stabilize.

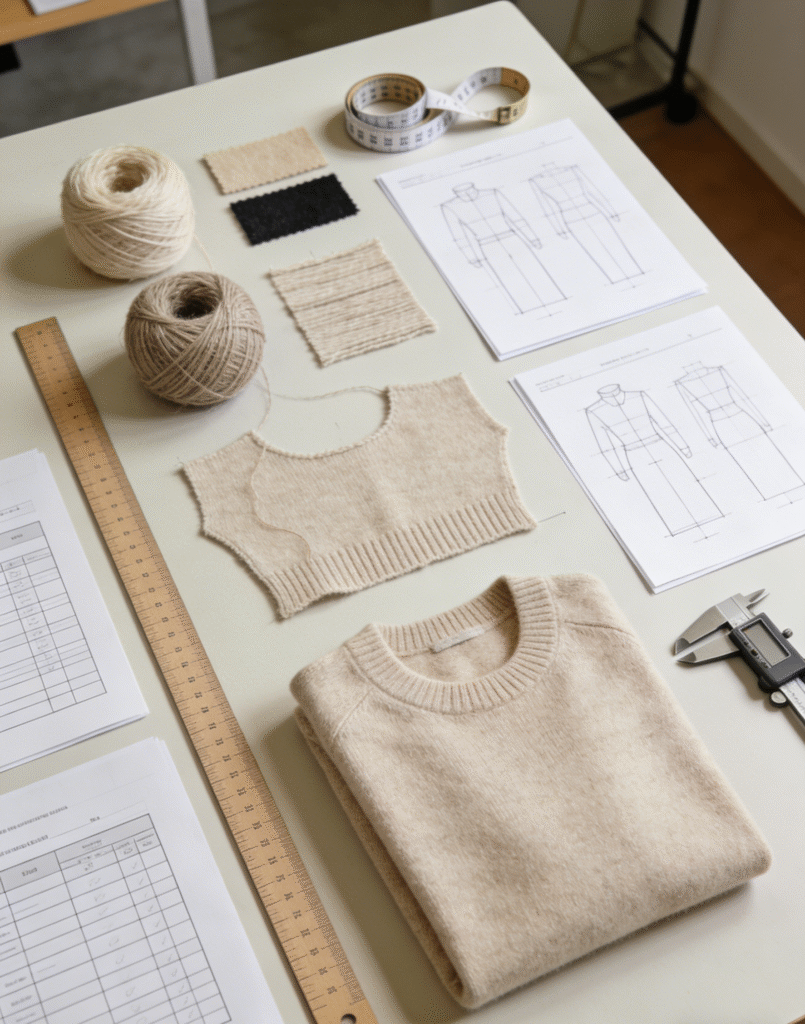

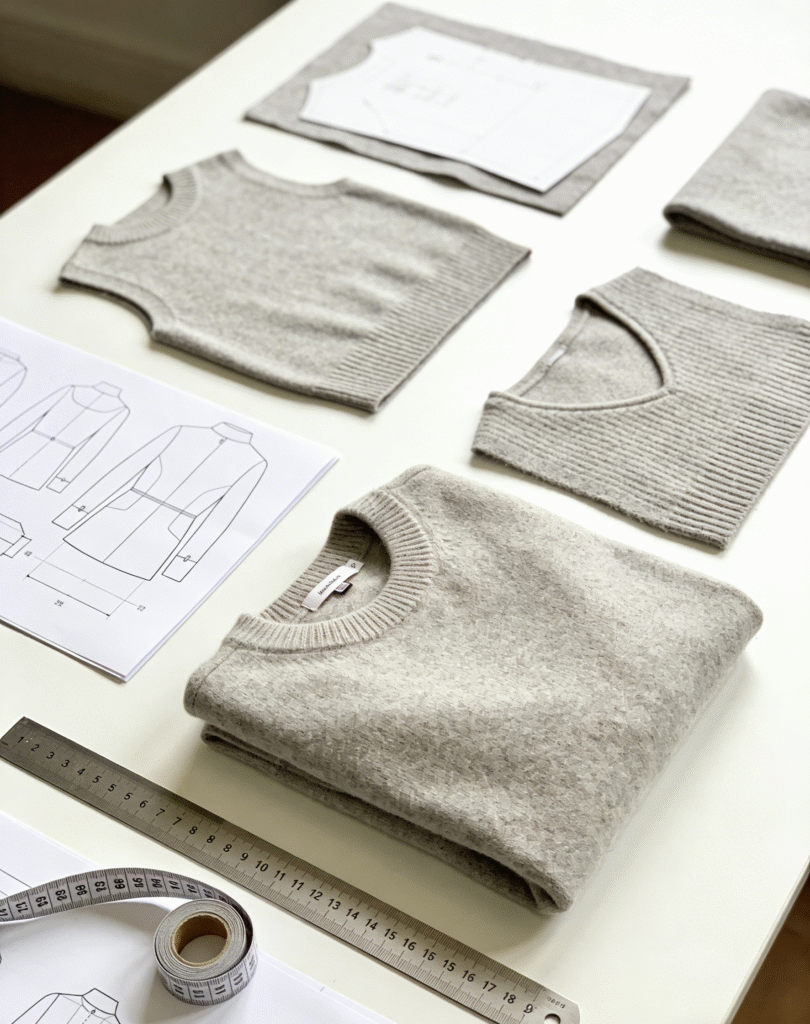

7. Sampling and Development: What Buyers Should Expect

Sampling is not just a design step—it is a technical validation process.

Typical Sampling Stages

- Proto sample (construction validation)

- Fit sample (size and silhouette)

- Sales or pre-production sample

Clear communication during sampling significantly reduces revisions and delays.

8. Lead Time Expectations in OEM and Wholesale Programs

Lead time depends on:

• Yarn preparation

• Sampling approval speed

• Order quantity

• Seasonal production load

Typical timelines:

• Wholesale: 30–45 days

• OEM: 45–75 days

Manufacturers value buyers who confirm specifications promptly and avoid last-minute changes.

9. Quality Control in Bulk Cashmere Sweater Production

Professional manufacturers implement quality control at multiple stages:

• Raw yarn inspection

• In-process knitting checks

• Post-wash measurement control

• Final random inspection

This multi-stage approach ensures consistency across large orders.

10. Managing Shrinkage, Pilling, and Shape Retention

These are the three most common quality concerns in cashmere sweaters.

Manufacturers control them through:

• Proper yarn selection

• Controlled washing processes

• Adequate finishing intensity

Reducing finishing steps may lower cost but increases risk significantly.

11. Packaging, Labeling, and Export Considerations

OEM and wholesale programs often include:

• Customized labels

• Hangtags and care labels

• Export-compliant packaging

Organizations such as the International Trade Centre (ITC) provide guidance on international trade compliance, labeling standards, and cross-border risk management for exporters. Manufacturers familiar with international shipping requirements reduce compliance risks.

12. Communication Mistakes That Delay Production

Common buyer-side issues include:

• Changing specifications mid-production

• Unclear size charts

• Late sample approvals

Clear documentation and stable specifications improve efficiency and reduce cost.

13. Why Early Manufacturer Involvement Improves Results

Early collaboration allows manufacturers to:

• Recommend suitable yarn and gauge

• Optimize cost-performance balance

• Identify potential production risks

This reduces development cycles and improves bulk success rates.

14. Long-Term Supplier Relationships vs One-Off Orders

From a manufacturer’s perspective, long-term cooperation enables:

• Better MOQ flexibility

• Priority production scheduling

• Continuous quality improvement

Buyers benefit from increased reliability and reduced sourcing risk.

15. How to Evaluate a Cashmere Sweater Manufacturer

When selecting a supplier, buyers should assess:

• Raw material control

• Yarn sourcing capability

• In-house knitting and finishing

• Quality control systems

• OEM and export experience

A strong manufacturer acts as a technical partner, not just a factory.

Final Thoughts

OEM and wholesale cashmere sweater production is a technical process that rewards preparation, transparency, and collaboration. MOQ, cost, and lead time are not independent variables—they are interconnected outcomes of manufacturing decisions.

For brands and wholesalers seeking stable, scalable sourcing, working with an experienced cashmere sweater manufacturer ensures consistency, efficiency, and long-term success.

For OEM or wholesale cashmere sweater sourcing, early technical alignment makes the difference.