Cashmere cardigans remain one of the most versatile knitwear categories across global markets. Search terms such as cashmere cardigan, women’s cashmere cardigan, and cashmere cardigan manufacturer consistently attract both consumer and professional traffic.

From a manufacturing perspective, however, cardigans are among the most technically demanding cashmere garments. Unlike pullovers, cardigans introduce front openings, closures, and additional stress points, all of which must be carefully engineered to preserve shape, appearance, and long-term wear performance.

This article examines the structural and technical considerations that define high-quality cashmere cardigan manufacturing, offering a manufacturer-driven perspective on materials, construction, finishing, and OEM production.

Table of Contents

- 1. Why Cashmere Cardigans Are More Complex Than Pullovers

- 2. Yarn Selection for Cardigan Stability

- 3. Ply Structure and Twist Optimization

- 4. Yarn Count and Visual Density

- 5. Knitting Gauge Selection

- 6. Stitch Density and Front Opening Control

- 7. Button Plackets and Closure Engineering

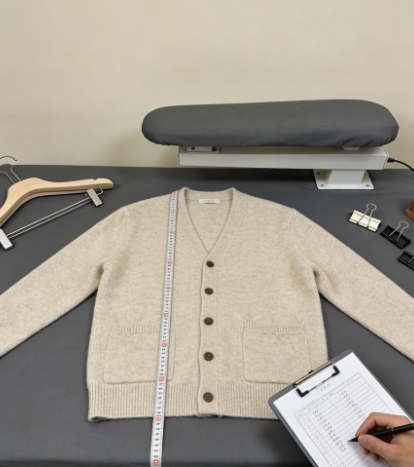

- 8. Button and Accessory Selection

- 9. Weight Standards for Cashmere Cardigans

- 10. Fit Engineering and Silhouette Stability

- 11. Finishing Processes Specific to Cardigans

- 12. Women’s Cashmere Cardigans vs Men’s Cardigans

- 13. Color Selection and Dye Control

- 14. OEM and Wholesale Considerations

- 15. MOQ Expectations for Cashmere Cardigans

- 16. Common Manufacturing Mistakes in Cardigan Production

- 17. Why Manufacturer Expertise Matters Most in Cardigan Programs

- Final Thoughts

1. Why Cashmere Cardigans Are More Complex Than Pullovers

Although visually similar to pullovers, cardigans place different mechanical demands on the fabric.

Key differences include:

• Vertical stress along the front opening

• Weight imbalance caused by buttons or plackets

• Increased risk of distortion at neckline and hem

Manufacturers must account for these factors during yarn selection, knitting, and finishing to prevent deformation over time.

2. Yarn Selection for Cardigan Stability

While softness remains important, structural stability takes priority in cardigan production.

Preferred Yarn Characteristics

• Longer fiber length for improved tensile strength

• Balanced fineness to reduce fuzzing

• Consistent ply structure

Many manufacturers recommend slightly stronger yarn specifications for cardigans compared to equivalent pullover styles.

3. Ply Structure and Twist Optimization

Cardigans benefit significantly from multi-ply yarn structures. According to Textile School, 2-ply or higher yarns improve yarn cohesion, tensile strength, and resistance to deformation. Moderate twist further enhances seam stability and durability around button areas, while excessive twist may compromise softness and drape.

Cardigans benefit significantly from:

• 2-ply or higher yarns

• Moderate twist levels

Higher twist improves:

• Seam stability

• Button area durability

• Resistance to stretching

Over-twisting, however, can compromise softness, requiring careful optimization.

4. Yarn Count and Visual Density

Yarn count directly affects visual density and fabric behavior. The NM (Number Metric) yarn count system, as defined by Wikipedia, measures how many meters of yarn weigh one gram, allowing manufacturers to precisely control garment weight, density, and consistency in cashmere cardigan production.

Common yarn counts used in cashmere cardigans include:

• 2/24 NM: structured, balanced look

• 2/26 NM: lighter, more refined drape

Manufacturers often select yarn count based on target market expectations and garment length.

5. Knitting Gauge Selection

Gauge influences both appearance and structural behavior.

Typical Gauge Options

• 9GG: most versatile and widely used

• 12GG: refined, lightweight cardigans

• 7GG: heavier, outerwear-style cardigans

For most women’s cashmere cardigans, 9GG provides optimal balance between elegance and stability.

6. Stitch Density and Front Opening Control

Stitch density must be adjusted to:

• Prevent front edge stretching

• Maintain button alignment

• Support garment weight

Manufacturers often reinforce front panels through tighter stitch density or additional structural techniques.

7. Button Plackets and Closure Engineering

The button placket is the most vulnerable area of a cardigan.

Key Reinforcement Techniques

• Double-layer plackets

• Tighter rib structures

• Stabilized seams

Buttons must be carefully selected and attached to avoid excessive weight stress.

8. Button and Accessory Selection

From a manufacturing standpoint, button choice affects both aesthetics and performance.

Considerations include:

• Weight relative to fabric

• Attachment method

• Durability through repeated wear

Manufacturers often recommend lightweight, smooth-surface buttons to minimize fabric stress.

9. Weight Standards for Cashmere Cardigans

Cardigans generally require slightly higher weight than pullovers to maintain structure.

Typical Finished Weight Ranges

• 260–320g: lightweight cardigans

• 320–380g: structured or longer styles

Consistent weight control ensures balanced drape and fit.

10. Fit Engineering and Silhouette Stability

Cardigans demand precise fit engineering due to their open-front design.

Manufacturers focus on:

• Shoulder stability

• Armhole reinforcement

• Balanced front-to-back length

Improper fit engineering often results in front panels pulling or sagging.

11. Finishing Processes Specific to Cardigans

Finishing plays a crucial role in cardigan performance.

Key processes include:

• De-hairing for surface refinement

• Steam shaping to stabilize front edges

• Controlled washing to reduce distortion

Cardigans typically require more intensive finishing than pullovers.

12. Women’s Cashmere Cardigans vs Men’s Cardigans

Women’s cardigans often emphasize:

• Finer appearance

• Lighter weight

• Decorative details

Men’s cardigans prioritize:

• Durability

• Neutral colors

• Simplified construction

Manufacturers adjust specifications accordingly.

13. Color Selection and Dye Control

Light and neutral colors dominate cashmere cardigan collections.

These shades require:

• Cleaner raw fiber

• Precise dye control

• Strict inspection standards

Manufacturers often advise starting with core colors before expanding palettes.

14. OEM and Wholesale Considerations

OEM cardigan programs involve:

• Custom sizing

• Brand-specific trims

• Packaging and labeling

Wholesale cardigans may use:

• Stock yarn

• Standardized designs

• Faster production cycles

Manufacturers help buyers choose the appropriate sourcing model.

15. MOQ Expectations for Cashmere Cardigans

Due to their complexity, MOQs for cardigans may be slightly higher.

Typical ranges include:

• 150–300 pcs per style/color using stock yarn

• Higher for custom designs or trims

Long-term partnerships often allow greater flexibility.

16. Common Manufacturing Mistakes in Cardigan Production

From a manufacturer’s perspective, frequent issues include:

• Insufficient placket reinforcement

• Overly soft yarn selection

• Ignoring button weight impact

Addressing these early prevents costly revisions.

17. Why Manufacturer Expertise Matters Most in Cardigan Programs

Cardigans magnify small technical errors. Experienced manufacturers:

• Anticipate structural challenges

• Optimize specifications early

• Reduce long-term quality risk

This expertise directly impacts garment longevity.

Final Thoughts

Cashmere cardigan manufacturing is as much engineering as it is craftsmanship. Structural reinforcement, yarn optimization, and finishing discipline distinguish durable, refined cardigans from those that lose shape prematurely.

For brands and wholesalers, partnering with an experienced cashmere cardigan manufacturer ensures reliable performance, consistent quality, and scalable production.

For cashmere cardigan OEM or wholesale sourcing, structural expertise defines quality. Onward offer you high-quality cashmere. Click here to contact us.